Choose the right biodegradable 3D filament

Please be aware, that we don’t sell filaments – we make parts and products from them

ENVI-1

Material based on potato starch, which is fully compostable at home or after burying in the soil. Great alternative to PLA. Certified by TÜV Austria. Depending on the size of some of its geometry and the thickness of its walls, the composting process can take from several weeks to several months. The quality of the composting environment is also important – the process will be different in a large and professionally created composter than in soil with a small number of plants and insects.

Thermoplastic starch is produced from raw materials certified according to EN 13432 for industrial composting. The raw materials are certified by TÜV Austria for composting under certain conditions of storage, temperature and humidity. Composting organic waste prevents it from being landfilled or incinerated. Composting is a biological process in which organic waste is broken down by microorganisms into carbon dioxide, water and humus – soil nutrients.

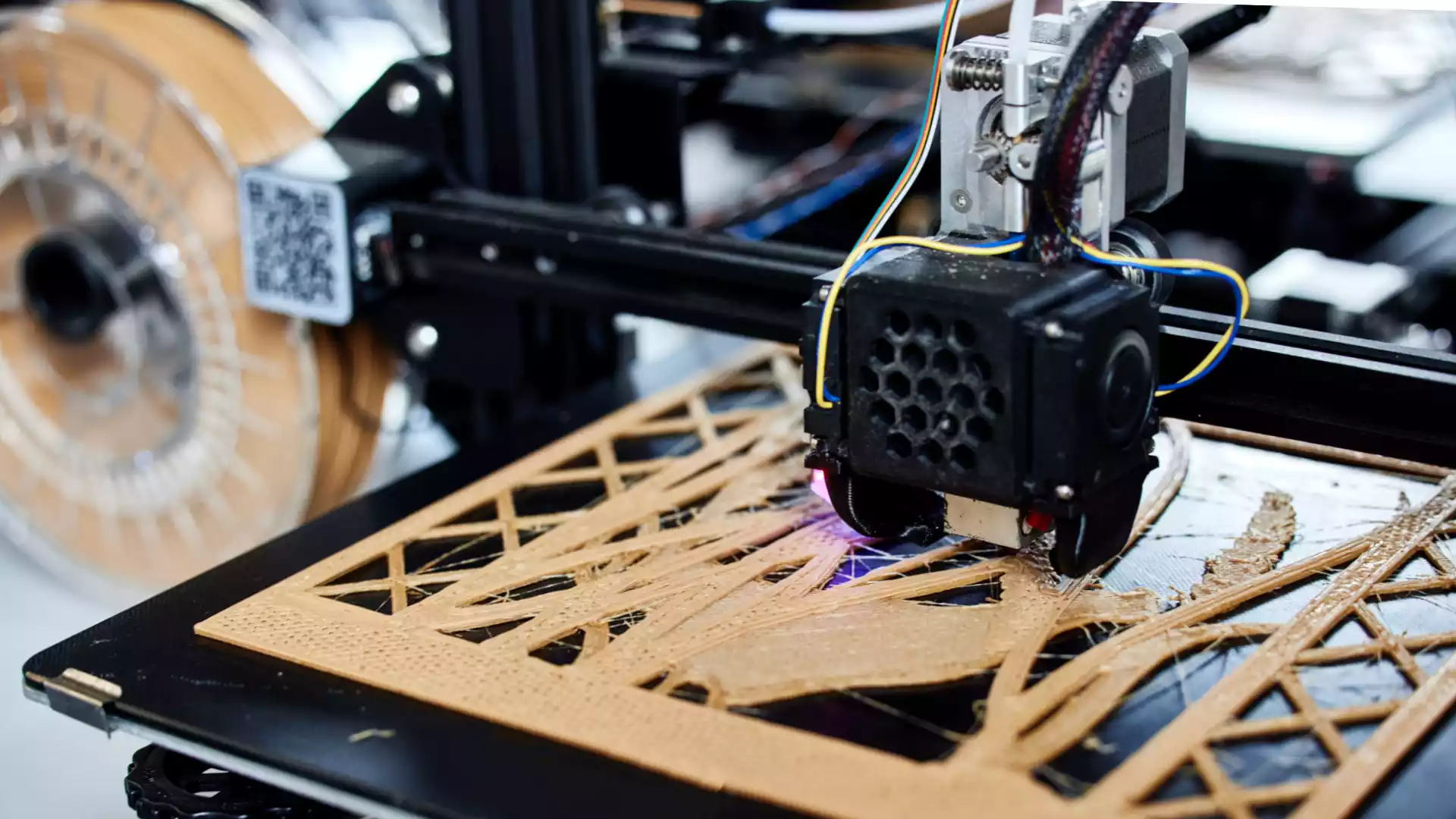

GF3D Branfill3d

Material based on raw wheat bran, which is a waste from pasta production. The material is biodegradable – parts disintegrate spontaneously within 10-16 months depending on storage conditions. GF3D Branfill3d is the original material of GREENFILL3D, which was used to create award-winning advertising stands – ECO POS. The material is based on wheat bran, PLA and other biocomponents.

The production of pasta results in a waste in the form of wheat bran. It is mixed with other natural and biodegradable materials (including PLA) and extruded on an industrial production line. We use several variants of filament saturation with wheat bran – from 5% to 20%. Higher saturation values - while possible, can prove problematic in ensuring continuous and trouble-free operation on 3D printers. The resulting filament has a standard diameter of 1.75 mm.

After 3D printing, the parts are resilient, flexible nad hard to break. At the same time, after a longer period (several months), the biodegradation process begins – the parts become stiffer and brittle.

PLA

One of the most popular bioplastics in the world. We can provide over 100 different colors and finishing variants – including tonal transitions (“rainbow” effect), color mixes (“magic” effect), glossy (“silk” effect), glitter and metallic. PLA is also great matrix for composite filaments, where they can be doped with wood, plaster or more specialized ingredients that improve strength and temperature properties.

An example of such material is Spectrum GreenyHT™ based on a high-performance biopolymer with a softening point (VICAT) up to 100°C and thermal resistance (HDT B) up to 90°C. The filament does not contain plasticizers and in terms of stiffness and hardness it significantly exceeds classic PLA types. Material remains fully biodegradable and compostable in industrial conditions specified in the EN 13432 standard. The bio-base comes from non-genetically modified sources (GMO-free).

Spectrum GreenyHT has a characteristic roughness on the print surface. On the one hand, it effectively masks the layers, and on the other hand, it strongly resembles 3D prints made using SLS or MJF technology.

ALGAE

Composite of PLA and algae-based biofiller. The 3D printed model can be additionally subjected to a heating process, consequently increasing its heat resistance. Available in two colors: natural (ivory) and pastel green.

HEMP

Composite of PLA and hemp-based biofiller. The 3D printed model can be additionally subjected to a heating process, consequently increasing its heat resistance. Available in one color: greenish beige.

STILLAGE (beer)

Composite of PLA and stillage-based biofiller. The 3D printed model can be additionally subjected to a heating process, consequently increasing its heat resistance. Available in two colors: light brown and dark brown.

Filaments gallery: