For several years, in the additive manufacturing industry, we have been witnessing the search for solutions that can be classified as sustainable and pro-ecological. Unfortunately, as in the case of other sectors of the economy, we are also dealing with the so-called „greenwashing”, but the fact is that 3D printing technology is, in principle, one of the „greenest” production methods.

One of the advantages of 3D printing over other manufacturing techniques are consumables and the relatively low level of waste that is generated during the production process. In the case of FDM / FFF technology, in which GREENFILL3D specializes, we are dealing with recycled materials on the one hand, and bioplastics on the other. From the very beginning of its activity, our company focused on the latter – materials that not only come from renewable resources, but also offer significant benefits for the environment.

Bioplastics: a sustainable alternative

Bioplastics come from natural resources such as corn starch, sugar cane and potatoes. Unlike traditional plastics based on fossil fuels (oil), bioplastics use crops that absorb CO2 as they grow, which can help reduce carbon emissions. PLA – a polymer made from fermented plant starch (mainly corn) and thermoplastic starch based on potato starch, are particularly preferred due to their biodegradability and low environmental impact.

At GREENFILL3D we primarily use PLA and potato starch due to their biodegradability and compostability, which is in line with our goal of minimizing waste in every product life cycle. These materials decompose under specific conditions into natural elements such as water, carbon dioxide and organic biomass, leaving minimal impact on the environment.

Application in 3D printing

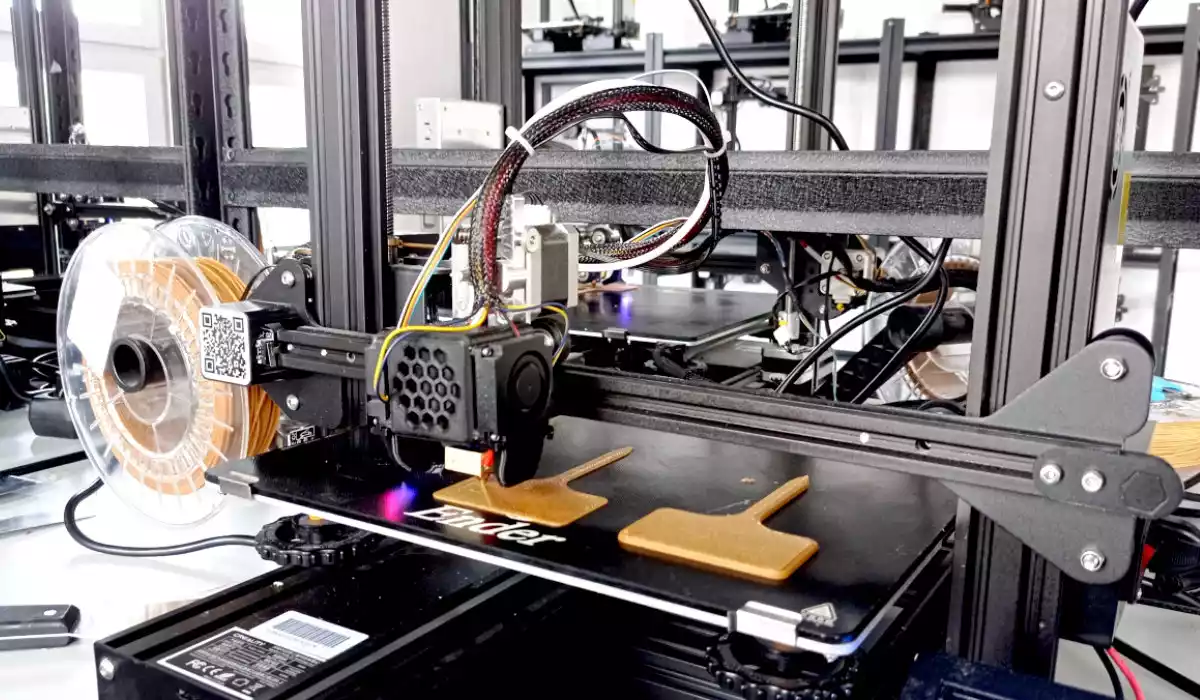

Using FDM/FFF technology, our 3D printers transform these bioplastics into a variety of products, from luxury interior design elements (offered under our COLORISED brand), through innovative tools for professional photographers (COLORISED.photo), to advertising tools and applications. The versatility and ease of use of PLA make it the basis of our production, minimizing the environmental impact of traditional plastics.

However, working with bioplastics is not without challenges. The sensitivity of materials to moisture and temperature requires precise control during the eco 3D printing process. This especially applies to potato starch and our proprietary material based on wheat bran. At GREENFILL3D, we have optimized additive manufacturing techniques to ensure that the unique properties of these materials are preserved, increasing the durability and functionality of the final products.

Environmental benefits of using bioplastics

The environmental benefits of using PLA and potato starch are enormous. By using bioplastics, we reduce our dependence on fossil fuels and reduce the overall carbon footprint of our products. Additionally, the compostability of these materials means that the products can return to the earth without leaving harmful residues.

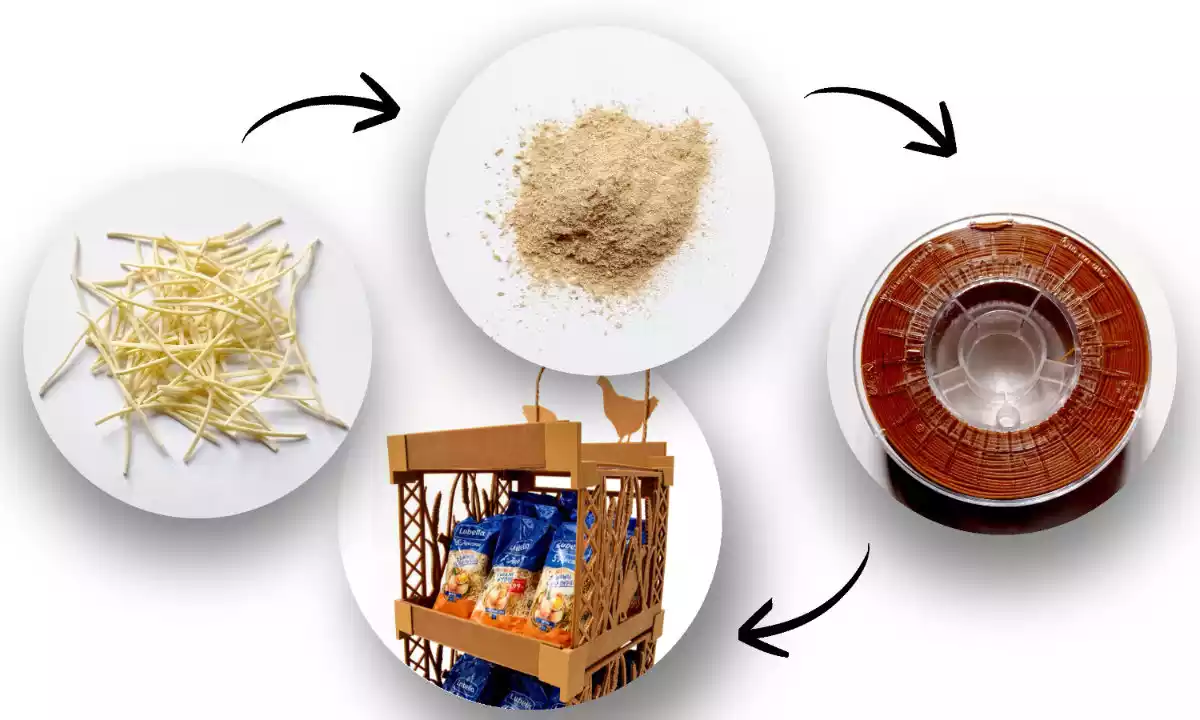

In addition, our ECO POS – innovative advertising stands are proof of the practical advantages of bioplastics. These stands were made of a composite material combining polylactide with wheat bran, which is waste from pasta production. This was a significant step towards sustainable commercial applications, demonstrating how industrial by-products can be reused into valuable, environmentally friendly products.

GREENFILL3D is a pioneer in the use of bioplastics in additive manufacturing – especially in the context of utility and commercial applications. We are committed to researching new materials and methods that support sustainable development. By incorporating PLA and potato starch into our production, we not only advocate for environmental responsibility, but also lead by example in the transition to ecological production. The process of mainstreaming bioplastics is complex, but a key step towards reducing our ecological footprint.