As countless examples have proven, 3D printing is a key tool in product and process development in virtually every segment of the economy. Nevertheless, the vast majority of the presented innovations concern very “serious” industries such as aviation, space, military, automotive, energy, medicine or jewelry, and the applications implemented using 3D printers are quite complicated and sophisticated. Meanwhile, there are areas where even the simplest products can provide a “major advantage”. Products as simple as… plastic circles.

Last year, GREENFILL3D – an award-winning Polish startup specializing in sustainable 3D printing, launched the COLORISED brand, dedicated to ecological solutions for luxury interiors. Since then, GREENFILL3D has presented several products eg. in the form of ECO Lampshades or full-color protective frames for light switches and electrical sockets. However, the scope of the company’s activities is incomparably wider and also includes a number of very niche and specialized products.

In 2023, the COLORISED brand debuted in the stretched ceiling industry – interior finishing applications that are very popular in several European countries. Stretch ceilings are made of foil or ecological fabrics, and are alternative to plasterboard or ceiling coffers. They are very simple and quick to install, both in commercial spaces (shopping malls, art galleries, entertainment facilities) as well as in houses and apartments. They allow to create very visually attractive lighting effects, where “the entire ceiling is lighting”. Installation of a stretch ceiling involves the contractor installing a structure of aluminum profiles on the ceiling and attaching foil or fabric to them. At the same time, he installs lighting in them (if the customer so requests).

While operating in this sector, GREENFILL3D met many contractors who reported the need for a number of solutions that would significantly facilitate their work, but were unavailable for sale due to their low scale or technological limitations. Below we present some very non-obvious and very simple applications that we made using additive manufacturing and which turned out to be a game changer in the stretch-ceiling interior finishing industry.

Protective rings for lighting installation

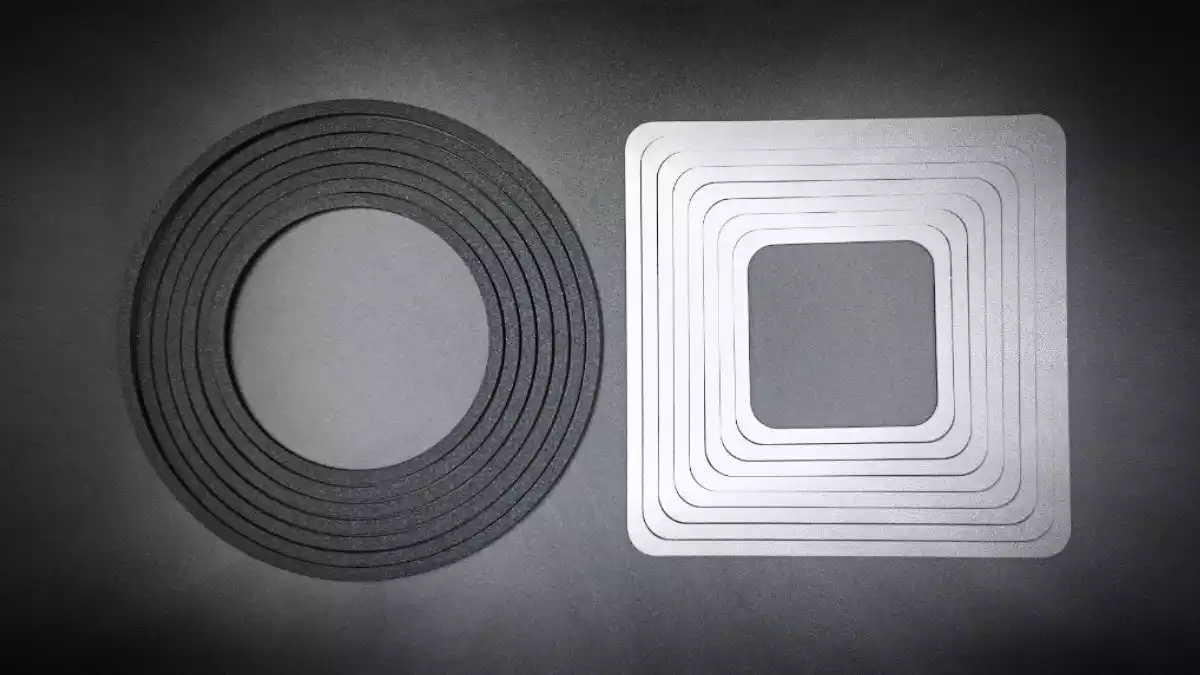

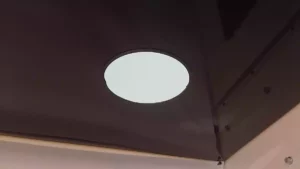

The most unusual – because trivial thing – are protective rings for mounting lighting on stretch ceilings made of PVC foil. The rings are made of two materials – ECO material with temperature resistance up to 98°C and self-extinguishing material with UL94 V0 certificate in accordance with the IEC 60695-11-10 standard. The rings come in two colors by default – black and white, in sizes from ⌀50 – ⌀355 mm, with a 5 mm increment in the diameter.

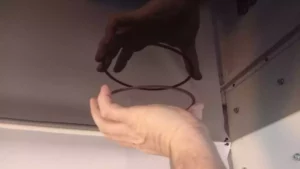

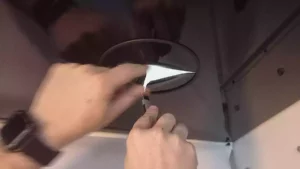

What are they for? When foil is stretched on the ceiling and the contractor wants to install lighting on it (e.g. hang a chandelier), he must cut an installation hole in its surface. To prevent the foil from tearing, he glues a protective ring in its place and cuts a hole inside it. The ring prevents the foil from tearing.

Why print them on 3D printers? Because the only rings on the market come from Russia (and there are sanctions there), Belarus or China and are:

- available to buy in only large quantity

- made of PVC, which is of quite poor quality (because it is very cheap)

- PVC is always transparent, which makes it difficult to stick to the ceiling (the adhesive layer is not visible so contractor doesn’t see where the glue is?)

- only available in certain sizes; making custom-sized rings requires the use of a laser plotter, but the contractor pays extra for waste material.

COLORISED protective rings have greater stiffness, can be non-flammable (while PVC burns), are colored to match the ceiling surface (usually white or black) and can have any shape, width, etc. (i.e. all the advantages of 3D printing).

Repair kit for PVC stretch ceilings

Sometimes a hole forms in the stretch ceiling… GREENFILL3D has created a repair kit that also serves as an inspection or ventilation grille. It works on the same principle as the protective ring.

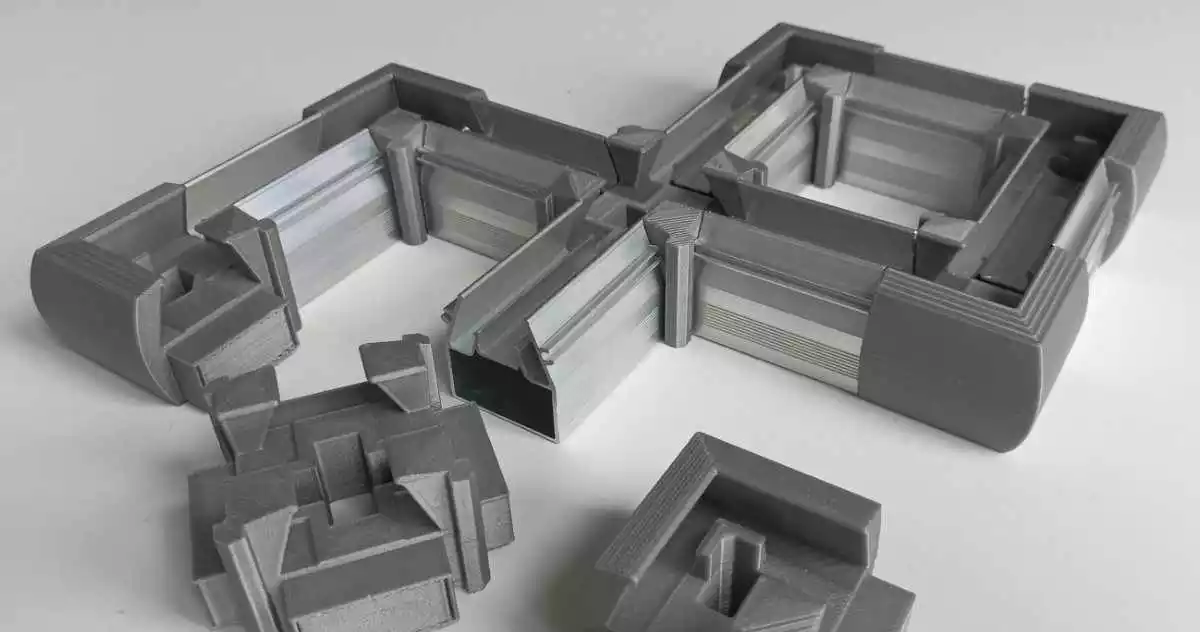

Connectors for aluminum profiles for the installation of stretch ceilings

Profiles for stretch ceilings are very specific and nuanced. They must not only provide for the installation of foil or fabric, but also provide space for LED strips that illuminate them. To create a sophisticated ceiling structure, profiles must be connected in different ways – sometimes at non-standard angles. They can be cut by hand and welded, but – it is quite difficult, it requires a welding machine and welding skills (in aluminum!). Some contractors can do it – most can’t. Therefore, GREENFILL3D has created a system for connecting profiles using simple and functional connectors.

No need to cut anything. No need to weld anything. Just insert the ends of the profiles into the connectors and mount the whole thing on the ceiling or wall. Moreover, the COLORISED connector system allows for better installation of LED strips than in the original aluminum profiles. For the contractor, this is a perfect solution because it solves many problems that he discovered on the construction site. The production of the connector takes only 1-2 hours of 3D printer operation. This can even be done on the same day. Due to the large number of mounting profile variants, the COLORISED portfolio includes over 20 designs.

A tool for installing masking seals in mounting profiles

Another rather non-obvious solution is C-Roller – a tool for fixing wall seals in aluminum profiles when tensioning ceiling fabrics. It can be personalized (with different colors or imprint of your own logo). They are a cheaper and more functional alternative to their Chinese counterparts, which are simply a metal ring mounted on an unaesthetic wooden handle (the whole thing wobbles because it is poorly fitted).

As we can see, 3D printing technology allows to “revolutionize” various areas of industry in a very inconspicuous way – even through “black and white circles” printed on demand. The described products are not only sustainable in terms of their production (3D printing using FFF technology is always more energy efficient than CNC milling or injection molding) as well as the speed of delivery of a non-standard solution (up to 2-3 hours from the time of placing the order).